Windows Door Frame Roll Forming Machine

- Product Description

Model No.: SF-M015

Brand: SUF

Types Of: Steel Frame &Amp; Purlin Machine

Applicable Industry: Hotels, Food &Amp; Beverage Factory, Printing Shops, Advertising Company, Farms, Building Material Shops, Machinery Repair Shops

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Germany, Turkey, Canada, Viet Nam, United Kingdom, United States, Brazil, France, Indonesia, Japan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Germany, Pakistan

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Gearbox, Bearing, Engine, Plc, Motor, Pressure Vessel, Gear, Pump

Old And New: New

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Packaging: NAKED

Productivity: 500 SETS

Transportation: Ocean, Land, Air, by train

Place of Origin: CHINA

Supply Ability: 500 SETS

Certificate: ISO 9001 / CE

HS Code: 84552210

Port: TIANJIN, XIAMEN, Shanghai

Payment Type: L/C, T/T, D/P, Paypal, Money Gram, Western Union

Incoterm: FOB, CFR, CIF, EXW, FCA, CPT, CIP

Features and Advantages of Window Frame Making forming Machine

Ground pit/overground accumulating unit, non-stop hole punching unit, and flying tracking cutting and automatic stacking devices are available for the choice to improve production speed greatly.

> Cassette type platform quick-change Machine base for multi-profile purposes is available for choice.

> With fully automatic non-stop standard configurations, the Max production speed can reach 30m/min

> Certified with Multi-Patents; CE Certified, EUROPEAN quality standard

> Most of hot & popular profiles models, we have ready Machines in stock for prompt delivery.

Window Frame Making Machine Introduction

This machine is used to make various frames. Our machine is for manufacture of steel window frame, steel door frame, bronze window frame, bronze door frame, fire rated window / door frame and so on.

Window Frame Making Machine Working Flow

Steel Window Frame Roll Forming Machine Roll formed door frames, from galvanized steel, Nowadays they have become more and more competitive. The whole door frame can be produce in one Roll Forming line through hole punching, forming, cutting to length, and the subsequent quick assembly.

Experienced engineers of SENUFMETALS Machinery are ready to serve for your unique profile metal frame production line. By SENUFMETALS Roll Former, increase production efficiency and reduce cost for steel door manufacturers. Other metal frame roll forming application are also available

Window Frame Profile Drawings

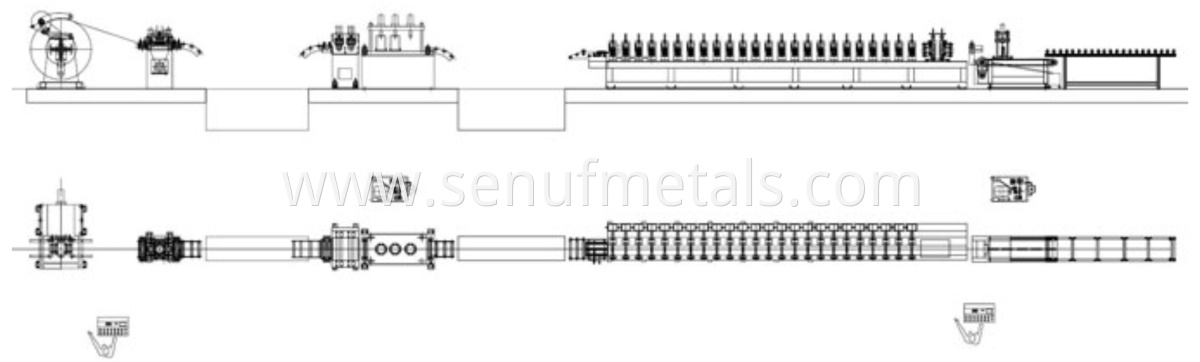

Window Frame Roll Forming Line Layout

Production line Components and Parameters

Related information

|

Machine Condition |

Fully New, A Grade quality |

|

Panel Shape |

As profile drawing and customer’s requirements |

|

Operator |

needed 1-2 persons |

|

Power Supply |

220V/380V/415V/460V, 50/60H乙 3P (as requests) |

|

Equipment Weight |

about 18t |

|

Dimension |

(L*W*H) about 25*3*2m |

|

LOADING SIZE |

Normally need 2 x 40′ container. |

|

Equipment Color |

normally Blue/White, or as requests; |

|

Place of Origin |

Hebei, China (Mainland) |

|

Packing |

Standard and careful export packing |

|

Decoiler |

3t/8t |

|

leveling device |

|

|

ground pit/ over ground accumulating unit |

(optional) |

|

Servo Feeding Device |

|

|

Holes punching device |

|

|

ground pit/ over ground accumulating unit |

(optional) |

|

Guiding device |

|

|

Roll forming system |

20/30m/min |

|

Safety cage |

optional |

|

Post cutting device |

flying cutting, tracking cutting and stop to cut are available for choice |

|

Output System |

Manual supporter/ Automatic Stacker (optional) |

|

Stackmaster Hydraulic system Electric control system |

(Output direction) Lateral/Longitudinal (optional) Power supply for holes punching /post-cutting system Touch screen brand: German Schneider Electric / Taiwan WEINVIEW, Inveter brand: Taiwan Delta, Encoder brand: Japan Omron (optional or as requested ) |

|

|

Product Categories : Cold Roll Forming Machine > Roller Shutter Door Forming Machine