Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SUF

Brand: SUF

Applicable Industry: Hotels, Food &Amp; Beverage Factory, Construction Works, Garment Shops, Energy &Amp; Mining, Farms, Building Material Shops, Home Use, Manufacturing Plant, Restaurant, Food &Amp; Beverage Shops

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Philippines, Spain, Chile, Ukraine

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Philippines, Spain, Algeria, Nigeria

Old And New: New

Machine Type: Tile Forming Machine

Tile Type: Steel

Use: Roof

Productivity: 30 M/Min

Place Of Origin: China

Warranty Period: More Than 5 Years

Core Selling Point: Easy To Operate

Rolling Thinckness: 0.3-0.8mm

Feeding Width: 1220mm, 915mm, 900mm, 1200mm, 1000mm, 1250mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2019

Core Component Warranty Period: 5 Years

Core Components: Pressure Vessel, Motor, Other, Bearing, Gear

Forming Speed: 10-15m/min

Certification: ISO

Usage: Floor

Tile Type: Colored Steel

Condition: New

Customized: Customized

Transmission Method: Machinery

Material Thickness Range: 0.2-1mm

RAW MATERIALS: Galvanized Coils, Pre-painted Coils, Aluminum Coils

Rollers: 15 Rows(according To Drawings)

Material Of Rollers: 45# Steel With Chromed

Voltage: 380V/3Phase/50Hz(according To Customers')

Packaging: Naked

Productivity: 500 sets / year

Transportation: Ocean,Land,Air,Express,by train

Place of Origin: China

Supply Ability: 500 sets / year

Certificate: ISO / CE

HS Code: 84552210

Port: XIAMEN,TIANJIN,shanghai

Payment Type: L/C,T/T,Paypal,D/P,D/A

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ

Corrugated roof production sheet Roll Forming Machine

Corrugated Roll Forming Machine is different from other productions. Corrugated Roof Production Sheet Line uses new technology. Corrugated Roof Sheet Roll Forming Machine are widely used in building. What's more, our Corrugated roof production sheet roll forming machine equipment can be designed and manufactured as customers' requests.

Working Flow:

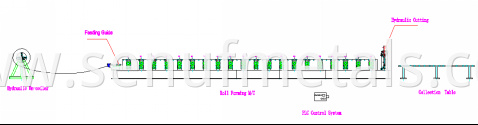

Decoiler - Feeding Guide - Main Roll Forming Machine - PLC Contol System - Hydraulic Cutting - Output Table

Components:

5 Tons Hydraulic Decoiler

Leveling

Main Roll Forming

Hydraulic station

PLC Control system

Hydraulic cutting

Receving table

Technical parameters:

1. Raw materials: Galvanized coils, Pre-painted coils, Aluminum coils

2. Material thickness range: 0.2-1mm

3. Forming speed: 10-15m/min

4. Rollers: 15 rows(according to drawings)

5. Material of rollers: 45# steel with chromed

6. Shaft material and diameter: 76mm, material is 45#

7. Material of body: 400H steel

8. Wall panel: 20mm Q195 steel(all with electrostatic spraying)

9. Controlling system: PLC

10. Main power: 5.5KW/7.5KW

11. Material of cutting blade: Cr12 mould steel with quenched treatment

12. Voltage: 380V/3Phase/50Hz(according to customers')

13. Total weight: about 5 tons

5 Tons Hydraulic Decoilers:

Inner Diameter: 450-600mm

Outer Diameter: 1500mmCoil Width: 1300mm

Leveling:

Keep materials straight, and the width can be adjusted by manual.

Main Roll Forming:

1. Machine frame: 400H Steel

2. Transmission: Chain

3. Forming steps: 16-20 steps

4. Shaft Diameter: 75mm

5. Roller Material: 45# steel with chromed

6. Forming Speed: 10-15m/min

7. Motor: 7.5KW

Hydraulic station:

1. Power of the oil pump: 4kw

2. Hydraulic oil :40#

Control System: PLC

Brand: Delta

Language: Chinese and English (as required)

Function: Automatic control the cutting length and quantity, easy to operate and use.

Hydraulic cutting:

Cutter Material: Cr12 mould steel with quenched treatment

Cutting Tolerance: ±1.5mm

Product Categories : Cold Roll Forming Machine > Corrugated Roof Sheet Roll Forming Machine

Home > Products > Cold Roll Forming Machine > Corrugated Roof Sheet Roll Forming Machine > Corrugated roof production sheet roll forming machine

Send Inquiry

Ms. he

Tel:86-311-88035278

Fax:86-311-88035278

Mobile Phone:+8615369176436

Email:top1@senufmetals.com

Address:NO.68 HEPING WEST ROAD, SHIJIAZHUANG CHINA, Shijiazhuang, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.