Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SUF

Brand: SUF

Applicable Industry: Hotels, Construction Works, Food &Amp; Beverage Factory

Out-of-warranty Service: Video Technical Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Philippines, Spain, Chile, Ukraine

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Philippines, Spain, Algeria, Nigeria

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 5 Years

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Pressure Vessel

Old And New: New

Species: Pipe Production Line

Pipe Material: Carbon Steel

Application: Drain Pipe

Place Of Origin: China

Warranty Period: More Than 5 Years

Core Selling Point: Easy To Operate

Motor Power: 7.5kw

Control System: PLC

Voltage: Customized

Application: Industry

Condition: New

Customized: Customized

Theory: Other

Type: Other

Thickness: 0.4-0.6mm

Forming Speed: 8-12m/min

Roller Stations: 14

Shaft Diameter And Material: 75mm, Material Is 45#

Driven: Gear Chain Transmission

Packaging: NAKED

Productivity: 500 SETS

Transportation: Ocean,Land,Air,Express

Place of Origin: CHINA

Supply Ability: 500 SETS

Certificate: ISO 9001 / CE

HS Code: 84552210

Port: XIAMEN,TIANJIN

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ,DDP,FAS,DES

Steel Downpipe Roll Forming Machine production line

Downspout Pipe machine is supplement to your seamless gutter machine, which can make both downspout pipe and elbow.

Main features of Steel downpipe Roll Forming Machine

In order to offer a complete gutter system --- and do it all "in-house" --- you need Downspout Pipe Forming Machine has following advantages:

1. Make both downspout pipe and elbows(with bending device for engineering convenience)

2. With square type downspout pipe nd round type downspout pipe for optional

3. Easy operation, low maintenance cost

4. Stable and efficient

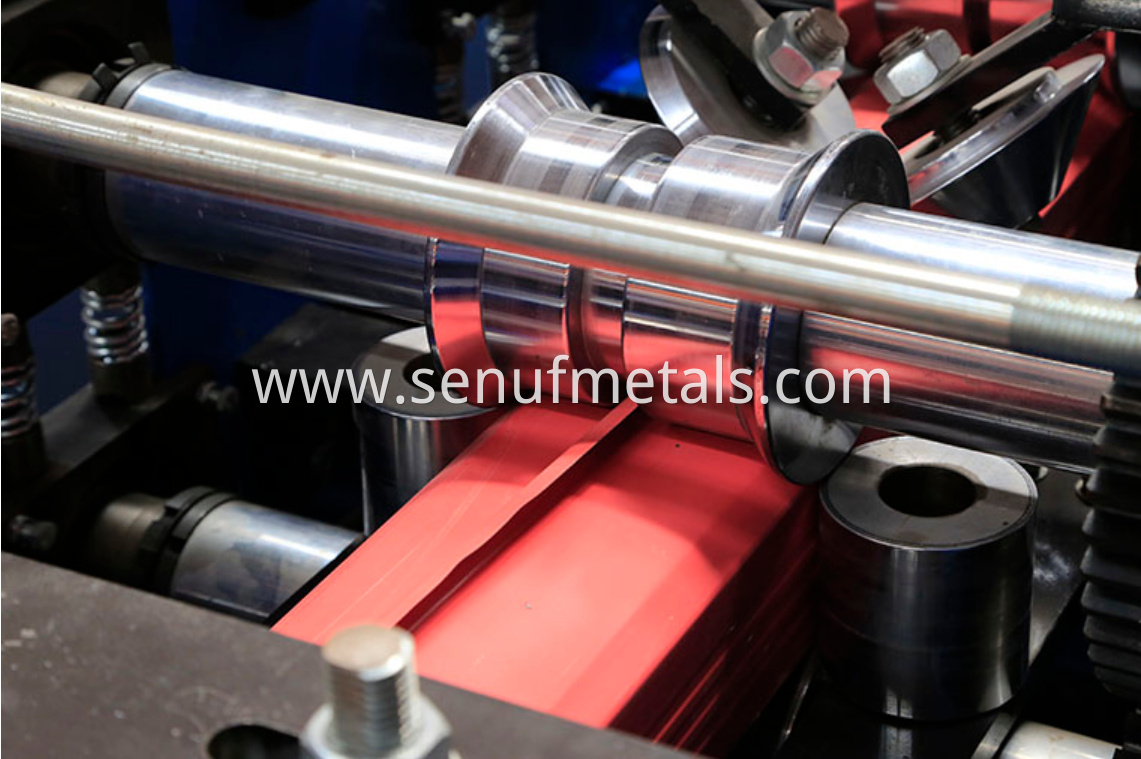

Detailed Images of Steel downpipe production line

Machine Parts

1. Steel downpipe Roll Forming machine production line tooth shape making device

Brand: SUF, Original: China

2. Steel downpipe roll forming machine production line rollers

Rollers manufactured from high quality steel 45#, CNC lathes, Hard-Chrome Coating for options.

With feeding material guide, body frame ade by 450H type steel by welding

3. Steel downpipe roll forming machine production line cutter

Made by high quality mold steel Cr12 with eat treatment,

Cutter frame made by high quality 20mm steel plate by welding

Hydraulic motor: 4kw, hydraulic pressure range: 0-16Mpa

4. Steel downpipe roll forming machine production line bender

5. Steel downpipe roll forming machine production line samples

6. Steel downpipe roll forming machine production line PLC control system

PLC control system (Touch screen brand: German Schneider Electric/Taiwan WEINVIEW, Inverter brand: Finlan VOCAN/Taiwan Delta/Alpha, Encoder brand: Omron)

7. Steel downpipe roll forming machine production line Decoiler

Manual decoiler: one set

Un-powered, manually control steel coil inner bore Shrinkage nd stop

Max. feeding width: 500mm, coil ID range 508±30mm

Capacity: Max 3 ton

With 3 tons hydraulic decoiler for option

6. Steel downpipe roll forming machine production line exit rack

Un-powered, one unit

Product Categories : Cold Roll Forming Machine > Downpipe Roll Forming Machine

Home > Products > Cold Roll Forming Machine > Downpipe Roll Forming Machine > Steel downpipe roll forming machine production line

Send Inquiry

Ms. he

Tel:86-311-88035278

Fax:86-311-88035278

Mobile Phone:+8615369176436

Email:top1@senufmetals.com

Address:NO.68 HEPING WEST ROAD, SHIJIAZHUANG CHINA, Shijiazhuang, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.